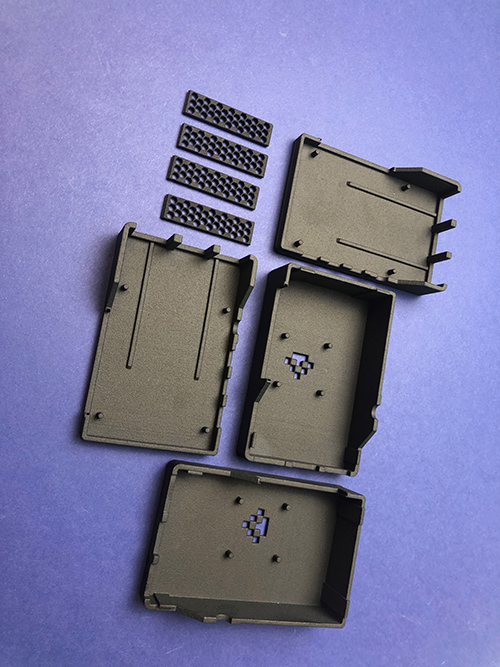

From manufacturers to hobbyists, and everything in between, on-demand manufacturing is increasingly becoming the go-to option for producing drone parts. In particular, 3D printing is paving the way for the affordable, customizable and accessible production of drones, where it can be produced in the factory, as well as the comforts of your home. The parts that can be 3D printed on a drone are as follows:

Propellers

Frame

Landing gear

Camera mounts

Antenna holder

Protective equipment (i.e. prop guards)

Remote casing

Battery pack casing

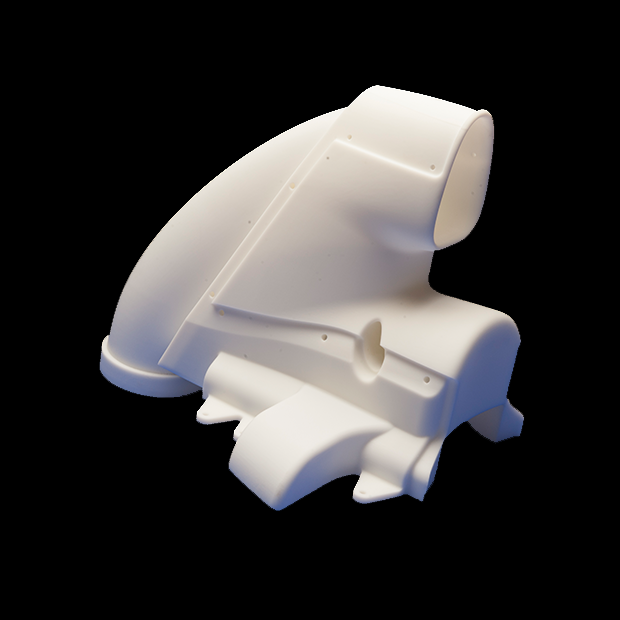

Using 3D printing, drones can be personalized and tailored to any individual’s needs, as well as offering an unrestricted manufacturing process, with testing and design iterations made possible for modifications and upgradations. 3D printing also allows for optimal performance for your drone in the production of lightweight parts, as well as easily accessible spare parts. However, 3D printing the parts yourself can take time, especially to the quality required for a fully operational drone. It requires skill, and practice, and a lot of the time, the 3D printed part may not be optimized.

This is where the on-demand manufacturing services offered by 3DCompare comes in. You can produce all the drone parts you need at volume to a high standard, with a variety of options available ensuring you get the exact products required to help produce your drones. Whether it’s 3D printing, or the other services offered through the 3DCompare on-demand manufacturing platform, like injection molding, you can produce large-batch drone parts with ease.

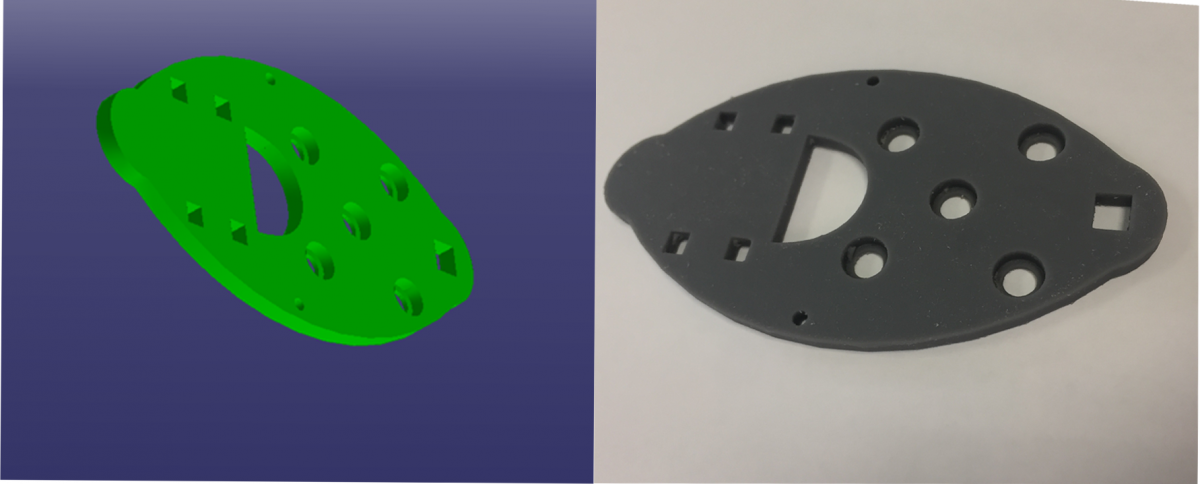

3DCompare has already been on the case, helping a drone company to produce large batches of their parts. They utilized the on-demand manufacturing platform that we provide to produce drone parts at volume, catered to their exact requirements. The drone company, using a CAD file that they supplied, was able to use 3DCompare to 3D print 1000 prototype drone parts made with ABS plastic, costing them £2,350. The part can be seen below:

Using the 3DCompare injection molding manufacturing service, 1000 drone parts generated from the same CAD file would have costed £3530, including tooling. Furthermore, the drone company had the option of a flexible and customizable manufacturing process using the 3DCompare 3D printing service, as designs can be edited and produced on demand. Injection molded parts however, are produced in large quantities according to a fixed mold, which can’t be adapted to the needs of the customer if a change in design is required. There is a storage cost included with injection molding as well, as parts are produced at mass within a short period of time. However, this also means that, large-batches of parts are produced at a faster rate with injection molding, with the possibility of increasing the number to levels of mass production. Injection molding also offers higher quality parts compared to 3D printing as well.

It is clear that, both options provide different benefits; whichever manufacturing option suits you however, the 3DCompare on-demand manufacturing platform will help produce the drone parts you need. Provide us with the CAD file for your drone part and we’ll compare prices and alternatives offered by different companies from our vast, global network of verified manufacturers to make certain your requirements are met. Choose the material you want for your drone from our comprehensive selection of material options, fit for any purpose. 3DCompare can even source a 3D file for you, if you have the concept of the drone part you want but haven’t generated a CAD design for it, using our CAD Designers service, allowing you to get the parts required to help your drone take flight.