Manufacturing Infomation

Pricing: $0.71/cm3

Pricing: $0.71/cm3

Minimum Cost:$22

Minimum Cost:$22

Lead Time: 4 days

Lead Time: 4 days

1000 x 800 x 500

2 x 2 x 2

0.016

±0.2% (with a lower limit of ±0.2 mm)

Suitable for:

Not Suitable for:

Colours Available

Colours Post Process

Additional Info

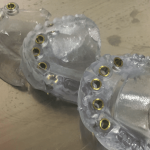

Biocompatible MED610, a PolyJet photopolymer, is a rigid material offering transparency and direct patient contact. Rapidly prototype medical and dental products including dental implant surgical guides and surgical orthopedic guides. VeroGlaze, MED620, an opaque material with A2 shading provides the best color match in the dental industry.

Biocompatible MED610 and MED620 materials are ideal for medical and dental applications requiring precise visualization and prolonged skin contact, up to 30 days skin contact and up to to 24 hours mucosal membrane contact. Biocompatible material has five medical approvals including cytotoxicity, genotoxicity, delayed type hypersensitivity, irritation and USP plastic class VI.

Features

Watertight

Watertight

Foodsafe

Foodsafe

Glue-able

Glue-able

Recycleable

Recycleable

Biocompatible

Biocompatible

Biodegradable

Biodegradable

Additive Manufacturing

Additive Manufacturing

Design Rules

The minimum detail is determined by the printer's resolution.When detail dimensions are below the minimum, the printer may not be able to accurately replicate them. Details that are too small can also be smoothed over in the polishing process.

To ensure details come out clearly, make them larger than the indicated minimum. We may refrain from printing products with details smaller than the minimum, since the final product will not be true to your design. If your product has details smaller than the minimum, try making them larger, removing them, or considering a material with finer detail.