Manufacturing Infomation

Pricing: $1.79/cm3

Pricing: $1.79/cm3

Minimum Cost:$48

Minimum Cost:$48

Lead Time: 6 days

Lead Time: 6 days

490 x 390 x 200

5 x 5 x 5

0.016, 0.032

±0.2% (with a lower limit of ±0.2 mm)

Colours Available

Colours Post Process

Additional Info

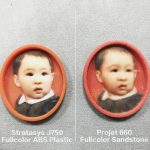

Unmatched Product Realism

The Stratasys J750™ 3D Printer delivers unrivaled aesthetic performance including true, full-color capability with texture mapping and color gradients. Create prototypes that look, feel and operate like finished products, without the need for painting or assembly, thanks to the Stratasys J750’s wide range of material properties. With an astounding 360,000+ color combinations to choose from and multi-material capability, the Stratasys J750 allows you to bring even your most imaginative ideas to life.

Maximum Versatility

Take advantage of unparalleled 3D printing versatility. Channel a range of applications that previously required multiple systems to achieve all in one package with a vast array of colors and material properties, from rigid to flexible and opaque to transparent, and the ability to print many diverse materials in one job or part. Print parts that feature Digital ABS Plus™ alongside a variety of flexible Shore A values and/or translucencies. With the fastest PolyJet multi-material 3D printer, you won’t sacrifce time for part intricacy and complexity.

Features

Watertight

Watertight

Foodsafe

Foodsafe

Glue-able

Glue-able

Recycleable

Recycleable

Biocompatible

Biocompatible

Biodegradable

Biodegradable

Additive Manufacturing

Additive Manufacturing

Design Rules

The minimum detail is determined by the printer's resolution.When detail dimensions are below the minimum, the printer may not be able to accurately replicate them. Details that are too small can also be smoothed over in the polishing process.

To ensure details come out clearly, make them larger than the indicated minimum. We may refrain from printing products with details smaller than the minimum, since the final product will not be true to your design. If your product has details smaller than the minimum, try making them larger, removing them, or considering a material with finer detail.