Manufacturing Infomation

Pricing: $21.43/cm3

Pricing: $21.43/cm3

Minimum Cost:$66

Minimum Cost:$66

Lead Time: 7 days

Lead Time: 7 days

250 x 250 x 280

3 x 3 x 3

0.05

± 3% of any dimension (and one layer thickness of 0.1mm)

Colours Available

Colours Post Process

Additional Info

About Stainless Steel 316L

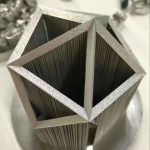

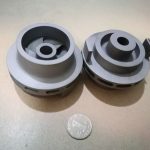

316L Stainless Steel printing is very accurate because of the fine coating resolution (30-40 µm) and the laser's accuracy. Unlike polymer powder sintering, stainless steel printing through DMLS requires adding base structures in order to attach the part to the board and to strengthen distinctive geometries like overhangs. The bases themselves are made from the same powder as the piece and will be taken off afterwards.

With no particular finishing, the material gives off a granular and coarse appearance, though suiting most applications. Smooth and shiny surfaces can be acquired after printing through finishing steps. Pieces can be machined, drilled, welded, electro-eroded, granulated, polished, and coated.

Benefits and Main Uses

Stainless Steel 3D printing is produced by fusion or laser sintering. Two possible technologies exist for this material: DMLS and SLM. At Sculpteo, we use DMLS (Direct Metal Laser Sintering) technology, a laser sintering technique on a EOS M290 machine to print stainless steel. The laser beam brings the metal powder close to its fusion point layer after layer in order to produce your object.

Since the stainless steel is melded at a very high temperature, the additive metallic production process requires vast technical mastery for initial studying of thermal and mechanical effects before 3D printing. It also requires excellent knowledge of finishing techniques for the object's completion.

To ensure successful production of your piece, having to modify your initial design is commonplace. Even if we must be repetitive, we prefer to warn you: if you wish to create a stainless steel piece just for curiosity, you risk being disappointed when confronting the necessary effort and cost of undertaking the project!

316L Stainless Steel is good material for printing both functional and spare parts in 3D. The material is easy to maintain because it attracts little dirt and the presence of chrome gives it the added benefit of never rusting.

316L Stainless Steel is used to offer solid pieces and essential hygienics in several industries such as the medical, aeronautical, automobile, and domestic products industries.

Features

Watertight

Watertight

Foodsafe

Foodsafe

Glue-able

Glue-able

Recycleable

Recycleable

Biocompatible

Biocompatible

Biodegradable

Biodegradable

Additive Manufacturing

Additive Manufacturing

Design Rules

The minimum detail is determined by the printer's resolution.When detail dimensions are below the minimum, the printer may not be able to accurately replicate them. Details that are too small can also be smoothed over in the polishing process.

To ensure details come out clearly, make them larger than the indicated minimum. We may refrain from printing products with details smaller than the minimum, since the final product will not be true to your design. If your product has details smaller than the minimum, try making them larger, removing them, or considering a material with finer detail.